Providing comprehensive plastisol services to protect metal

ISO CERTIFIED 9001:2015 complete dip coating, molding, and fluidized bed powder coating service. Our extensive industry knowledge and quick turnaround lead-times help you determine the most effect process for your products.

Aztec manufactures a wide range of plastic products using automated state-of-the-art equipment. Our products include tips, caps, protective covers and guards, handle grips, sleeves, and custom coatings.

Medical instrument tip protector caps and guards

Aztec dip molds medical tips and caps that offer protection for surgical instruments during handling and sterile processing.

We offer specialized secondary services for customer required specifications for punch and venting, package and labeling.

Specifications

Available properties

Thermal Insulation, Stress and Impact Resistant, Electrical Insulation, Corrosion Resistance, Sound Deadening, Wear Resistance, Vibration Dampening, UV Resistance

Available finishes

Decorative Finish, Finishes from Matte to Glossy, Standard Colors, Custom Colors, Partial Coating

Finish thickness

.030″ to .250″

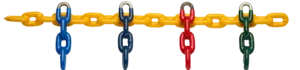

Plastisol Dip Coating

Plastisol coatings are composed of plasticized resin and PVC particles, which add properties such as impact-resistance or thermal insulation to metal parts. Heated metal objects are dipped into a pool of liquid plastisol and then cured, resulting in repeatable, uniform high quality coating suited to high volume orders.

Our proprietary process results in extremely consistent coating thicknesses, making dip coating the preferred choice for hand tools, utensils, clamps, clips, plating racks, hooks, brackets, playground decking, and fencing panels.

- Dual wall – double dip – 2 material double dip coating for dual wall insulated tools.

- Large coat capabilities – Servicing marine decking, playground and commercial outdoor benches, tables, and furniture.

- Short to long runs – Production runs of up to 100,000 items

Plastisol dip molding

Aztec offers a wide variety of caps, grips and sleeves in numerous stock sizes. Our products are used in extreme environments and outdoor applications. Our product applications include:

- Dock caps

- Plugs

- Thread protectors

- Maskings

- Finger & handle grips

- Custom size and materials

Dual wall – double dip material molded products

Dual wall for added protection and custom appearance. When combined with an outer layer of foam and an inner layer of durable higher durometer material, the results provide a snug puncture resistant fit with an ergonomic and softer feel.

Double dipping allows for more flexibility with product appeal to your product. Our double dipped products are found on electrical tools, pliers, wire cutters, lawn and garden tools and equipment, exercise equipment, recreational and many other industrial and retail items.

Specifications

Available properties

Thermal Insulation, Stress and Impact Resistant, Electrical Currents, Corrosion Resistance, Sound Deadening, Wear Resistance, Vibration Dampening, UV Resistance

Available finishes

Finishes from Matte to Glossy, Standard Colors, Custom Colors

Finish thickness

.030″ to .180″

Specifications

Available properties

Thermal Insulation, Stress and Impact Resistant, Electrical Insulation, Corrosion Resistance, Sound Deadening, Wear Resistance, Vibration Dampening, UV Resistance

Available finishes

Decorative Finish, Finishes from Matte to Glossy, Standard Colors, Custom Colors

Finish thickness

.007″ to .015″

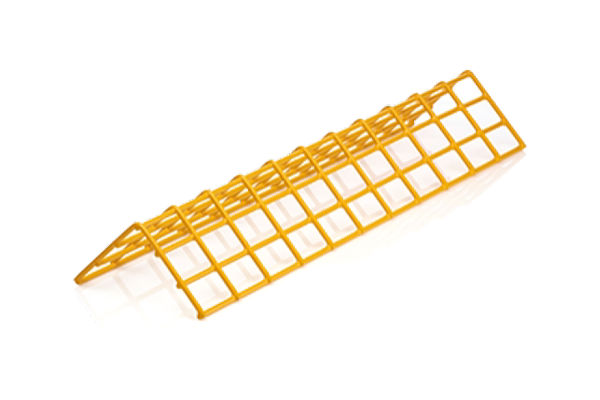

Fluidized bed powder coating

Fluidized bed plastisol coating is a metal coating technique where heated parts are immersed and vibrated in a powder coating to obtain a uniform thickness and then cured. This method is ideal for covering wire forms, irregular shaped parts, sheet metal and stampings providing a coating that will cover the entire product, even hard-to-reach wire cross welds.

- Aztec can accommodate both small and large scale items.

- Short to long production runs of 100,000 items.

- Eliminate the need to source raw materials from multiple vendors.

- Wide selection of coating materials with a range of properties.

Additional services and operations

Tooling assistance

Aztec is equipped with a full functioning internal CNC machine shop with state-of-the-art equipment and Engineering services that provide the ability to go from prototype to full production.

Tooling costs

The tooling costs and lead times for dip molding are significantly less in comparison than other plastic product manufacturing processes.

Secondary operations

- Pad printing

- Cutting, punching, and slitting

- Packaging and labeling